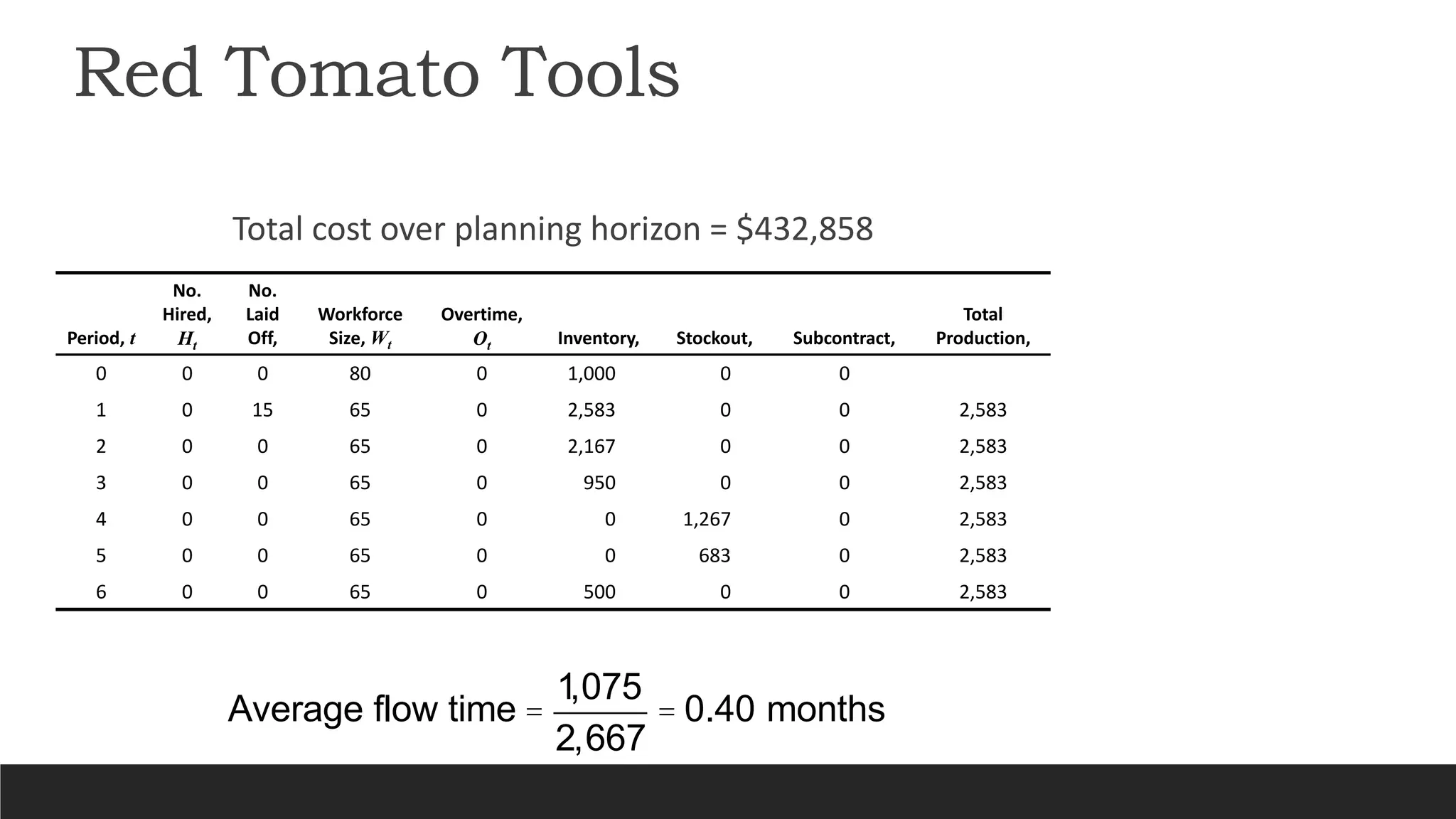

The document discusses aggregate planning in supply chains. Aggregate planning determines production levels, inventory levels, capacity levels, and backlogs over a planning horizon (typically 3-18 months) to maximize profit given demand forecasts. It aims to balance production, inventory, and capacity costs. The document outlines the aggregate planning problem and process, including information needed, strategies like chase, level, and time flexibility, and tools like linear programming. It provides an example of aggregate planning for Red Tomato Tools and discusses implementing aggregate plans in practice.