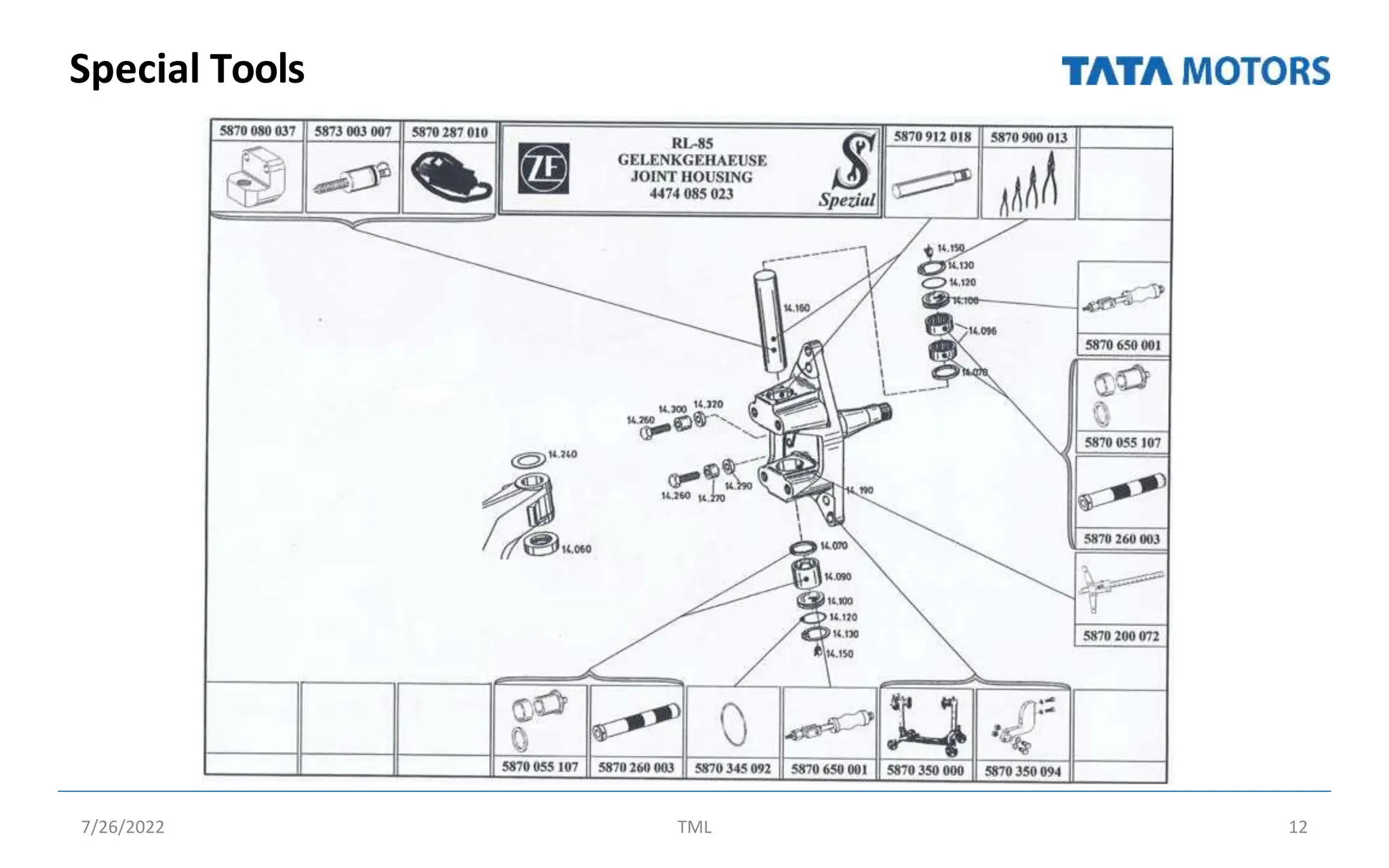

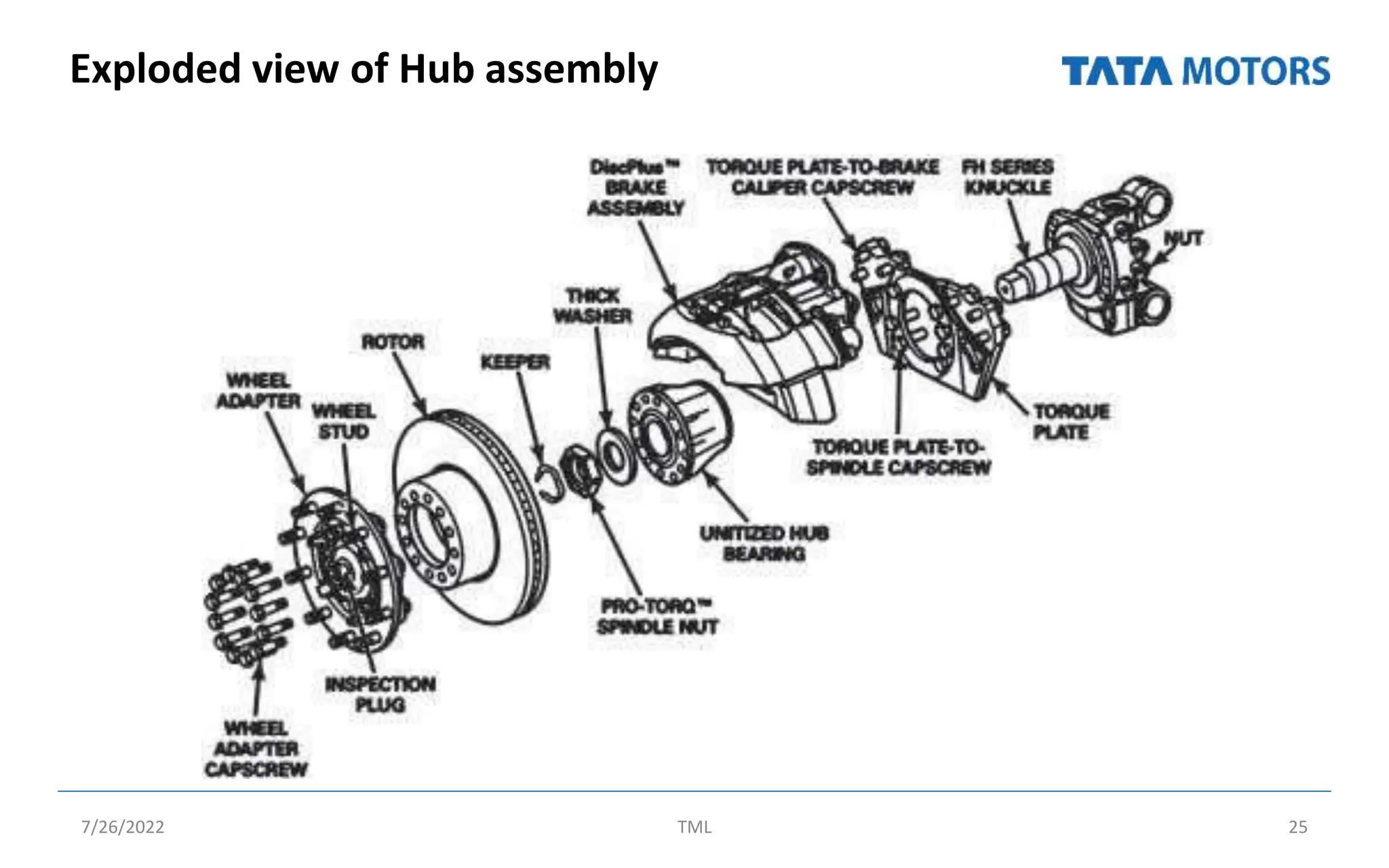

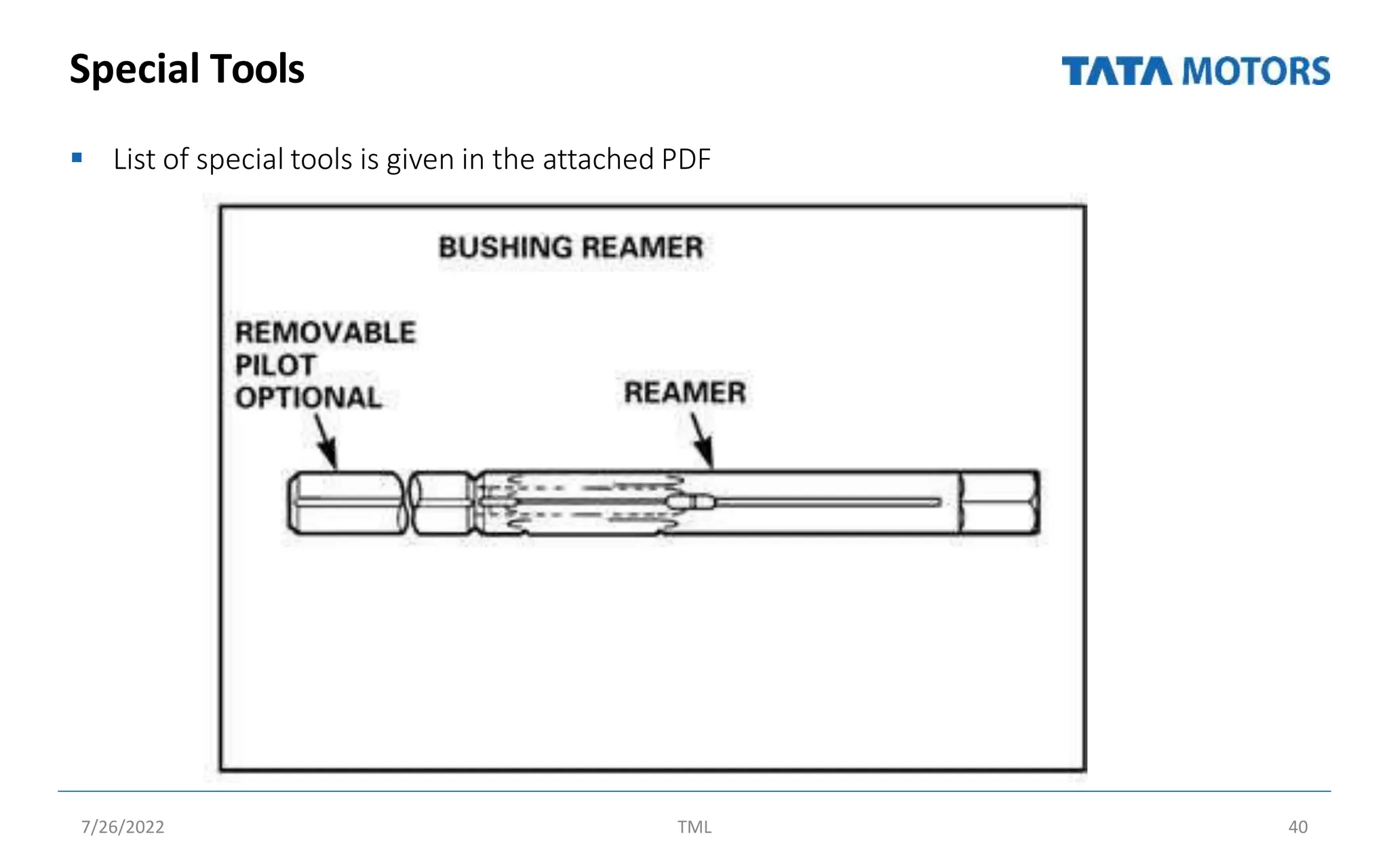

This document outlines the training module for Technician Level 2 focusing on axle systems, including objectives to perform basic checks, preventive maintenance, and disassembly/assembly of various axle systems. It includes technical specifications for different axle models such as ZF RL 85 A, Meritor FH 946, and ZF RL 75 E, along with practical exercises and the necessary special tools for training. The program aims at enhancing participant skills in inspecting and maintaining axle systems in Tata Motors vehicles.