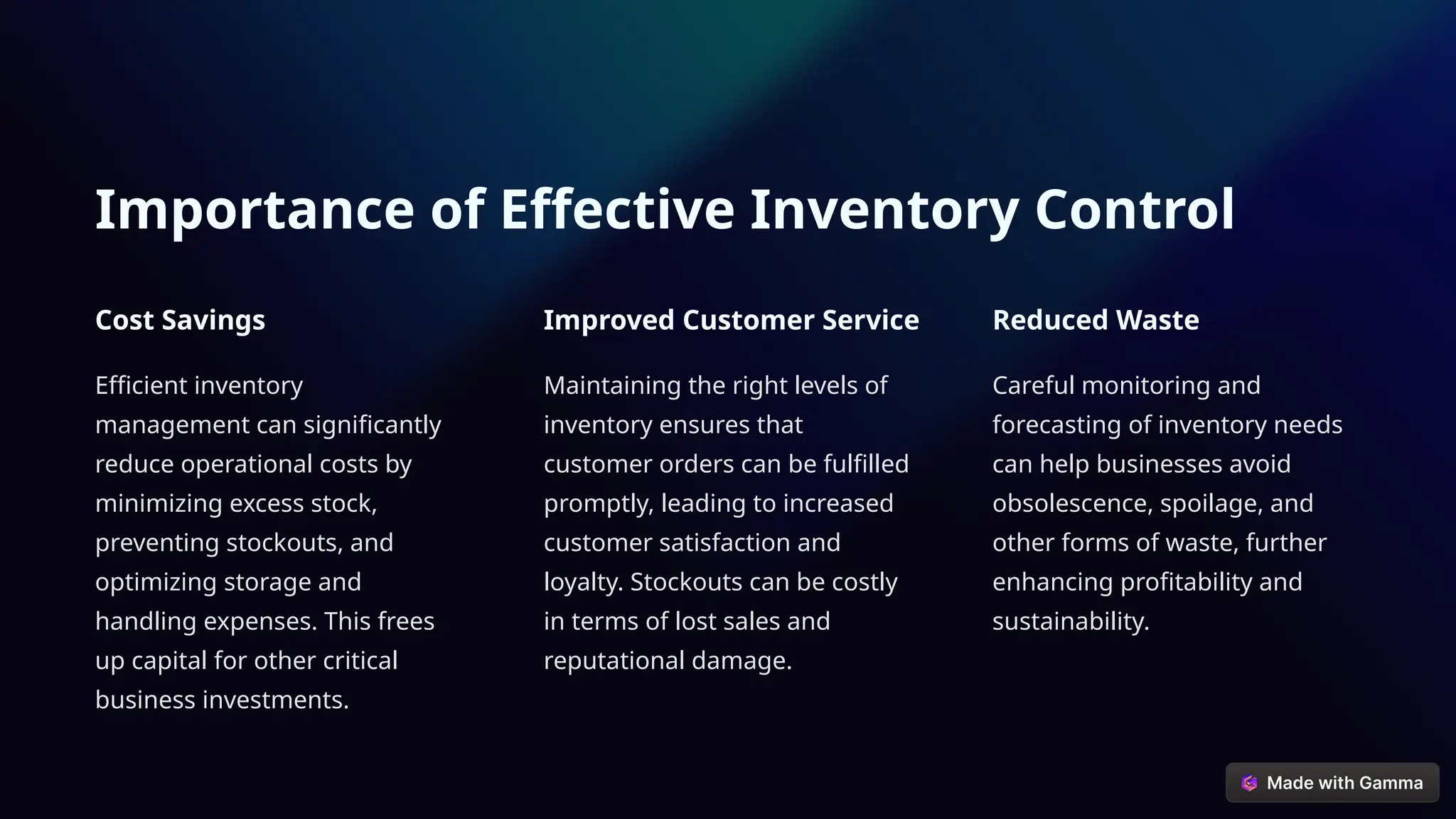

Effective inventory management is essential for business success, involving careful planning and tracking of stock to meet customer demand while minimizing waste. Strategies such as ABC and XYZ analysis, along with techniques like EOQ and JIT replenishment, are vital for optimizing inventory levels. Leveraging technology for tracking and analytics enhances decision-making and integrates inventory management with other business functions to ensure continuous improvement.