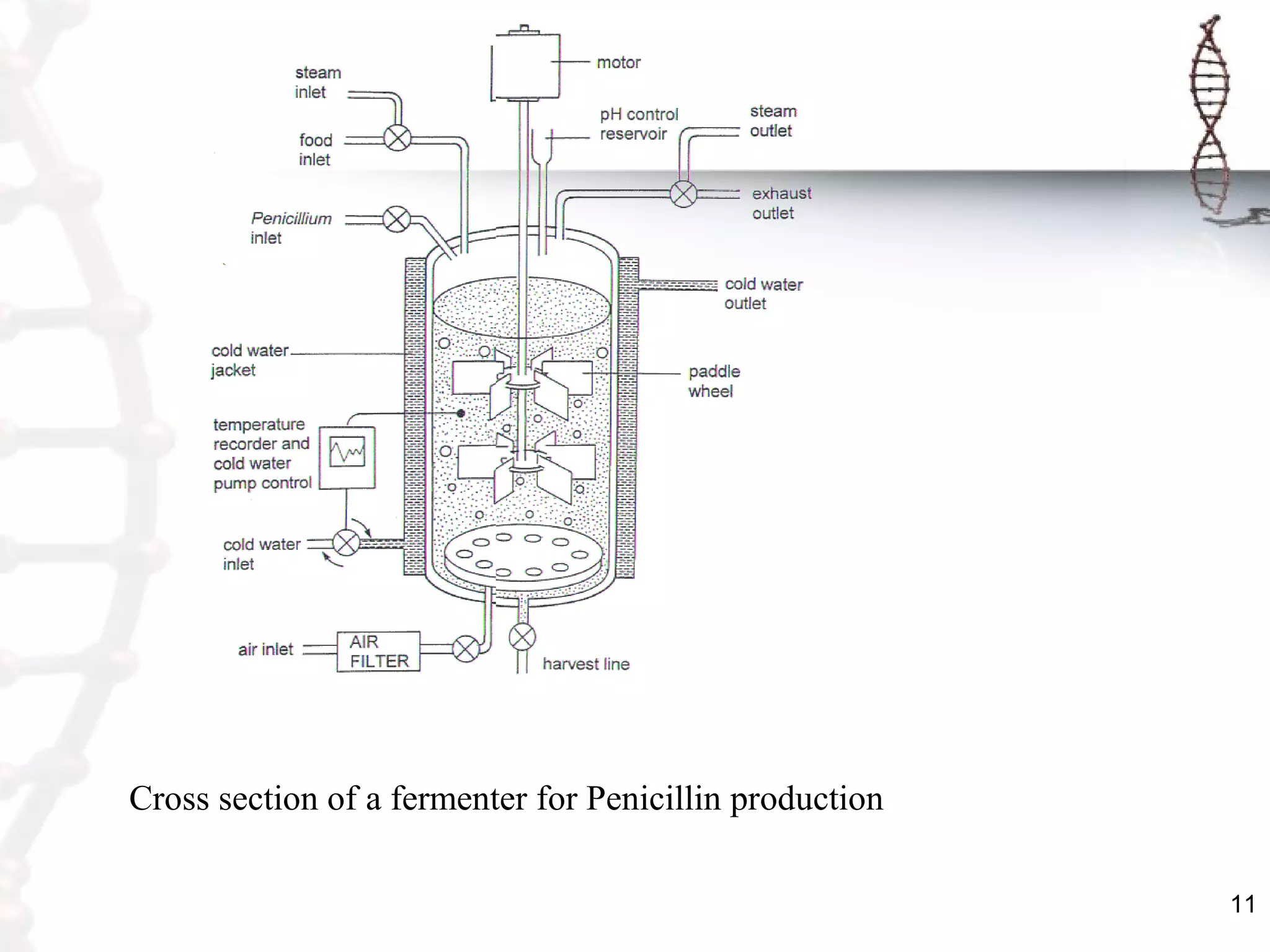

This document discusses the principles and techniques of large-scale microbial fermentation, highlighting the distinction between surface and submersion techniques used for producing microbial products. It details key microbial products and their corresponding organisms, outlines the fermentation process including the use of fermenters, and emphasizes the significance of the fermentation medium. Additionally, it addresses various contamination issues faced in microbial fermentation, including bacterial, viral, fungal, and dairy contamination, and their potential impacts on production yields.