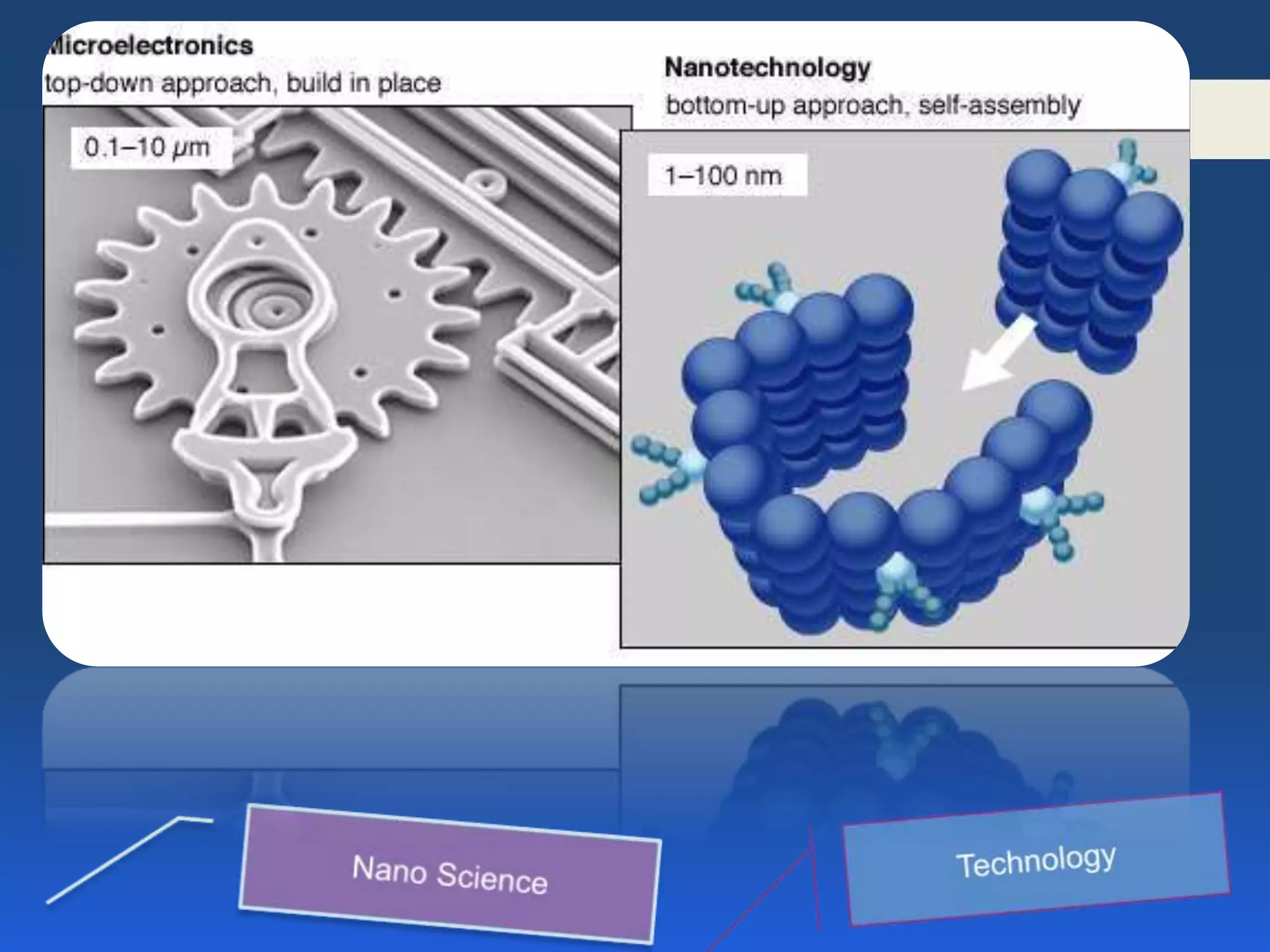

The document discusses the synthesis of nanoparticles through top-down and bottom-up approaches, detailing various methods such as sol-gel processes, mechanical attrition, and lithographic techniques. It emphasizes the importance of integrating both strategies for effective nanofabrication and highlights the advantages of each approach in producing structures at the nanoscale. Additionally, it explores the role of self-assembly in bottom-up methods, drawing inspiration from biological systems.