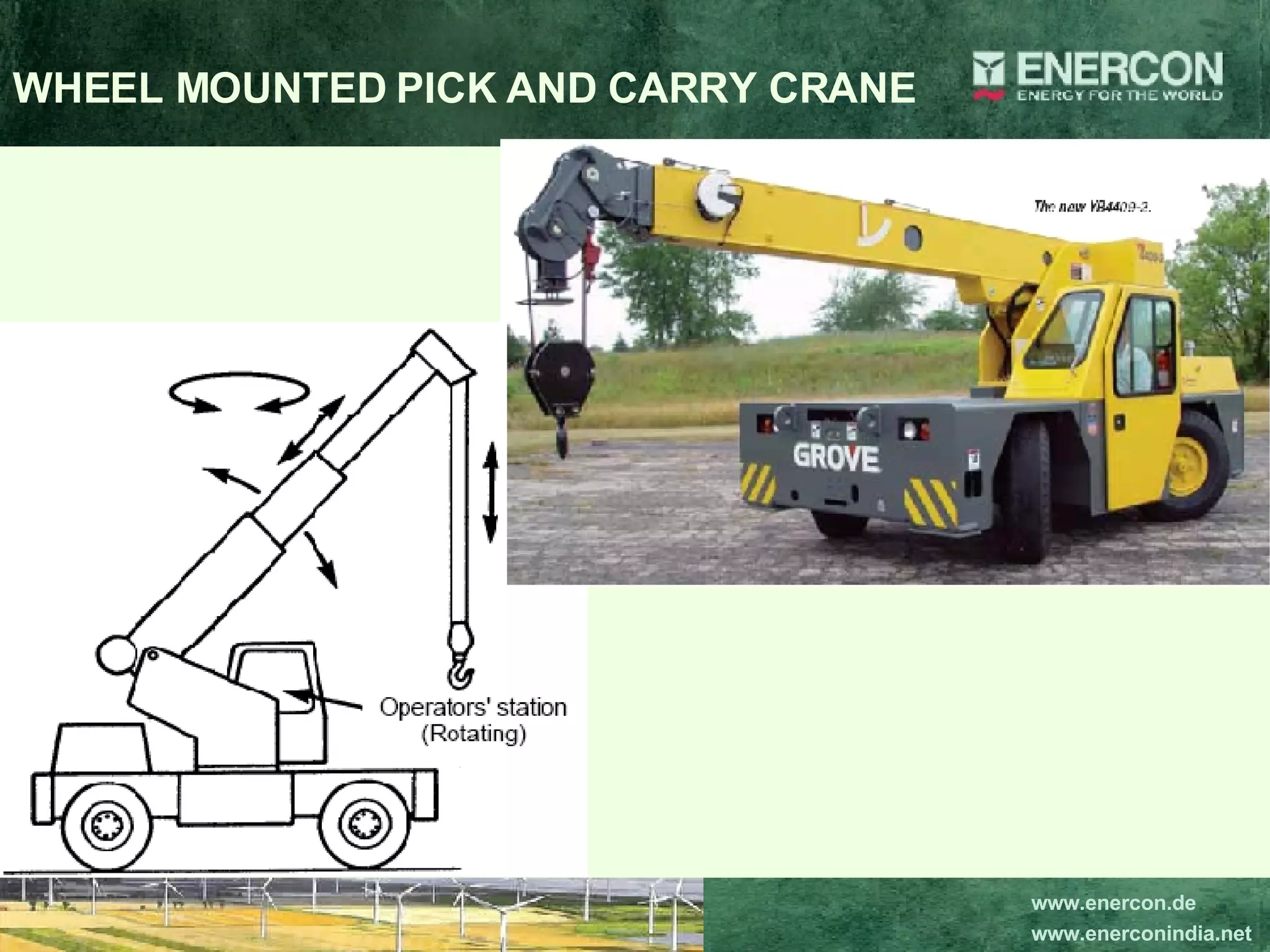

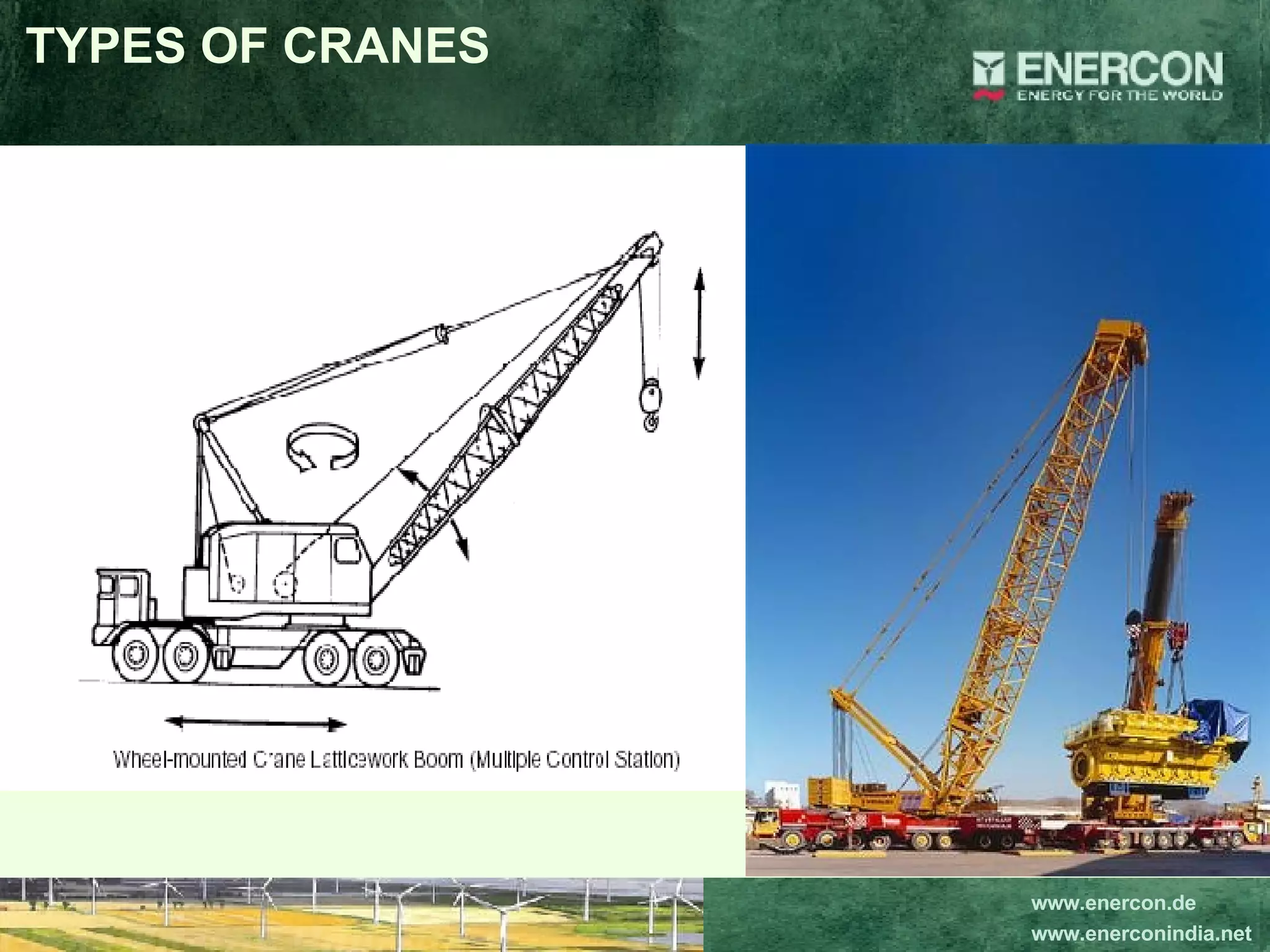

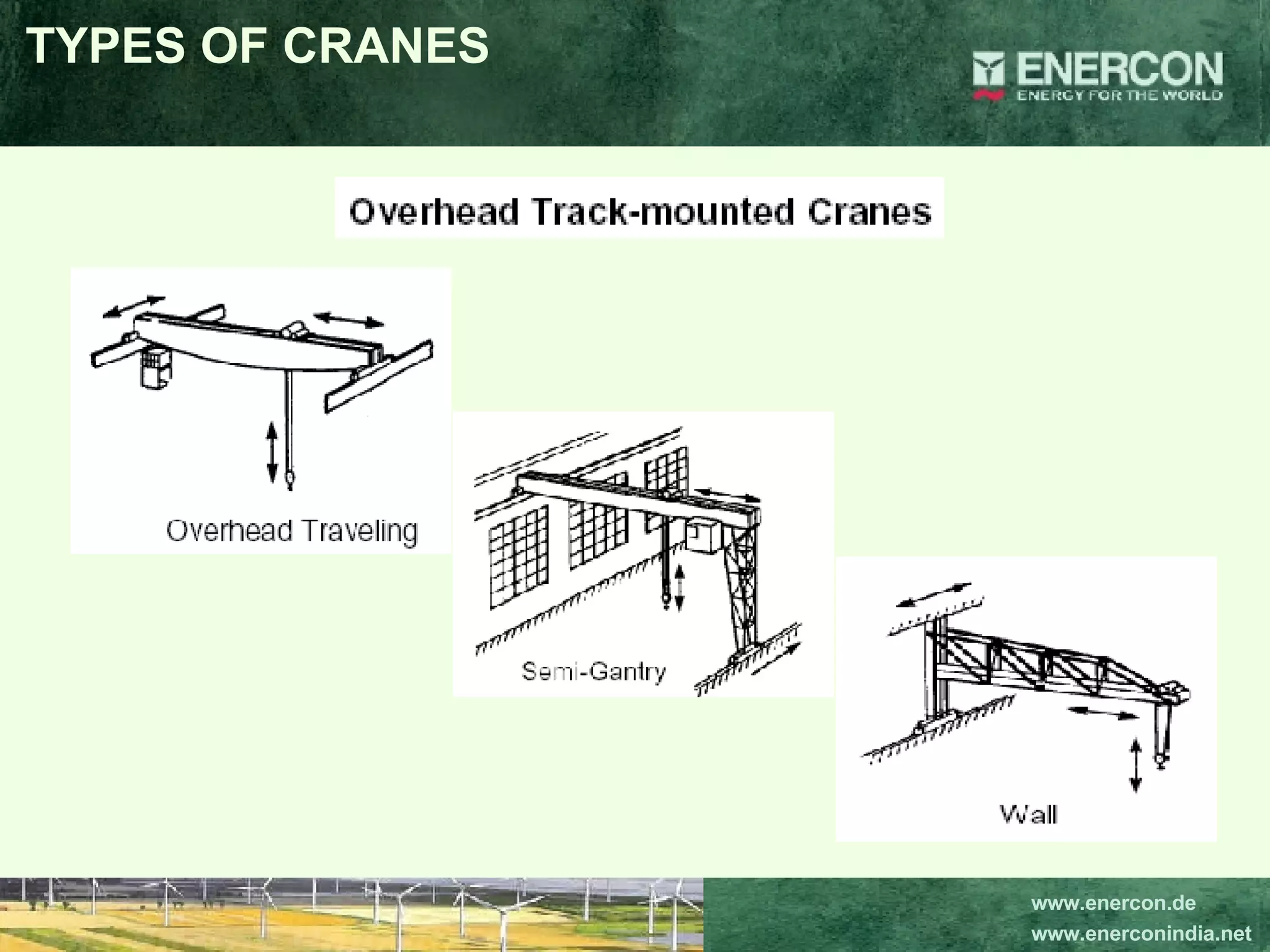

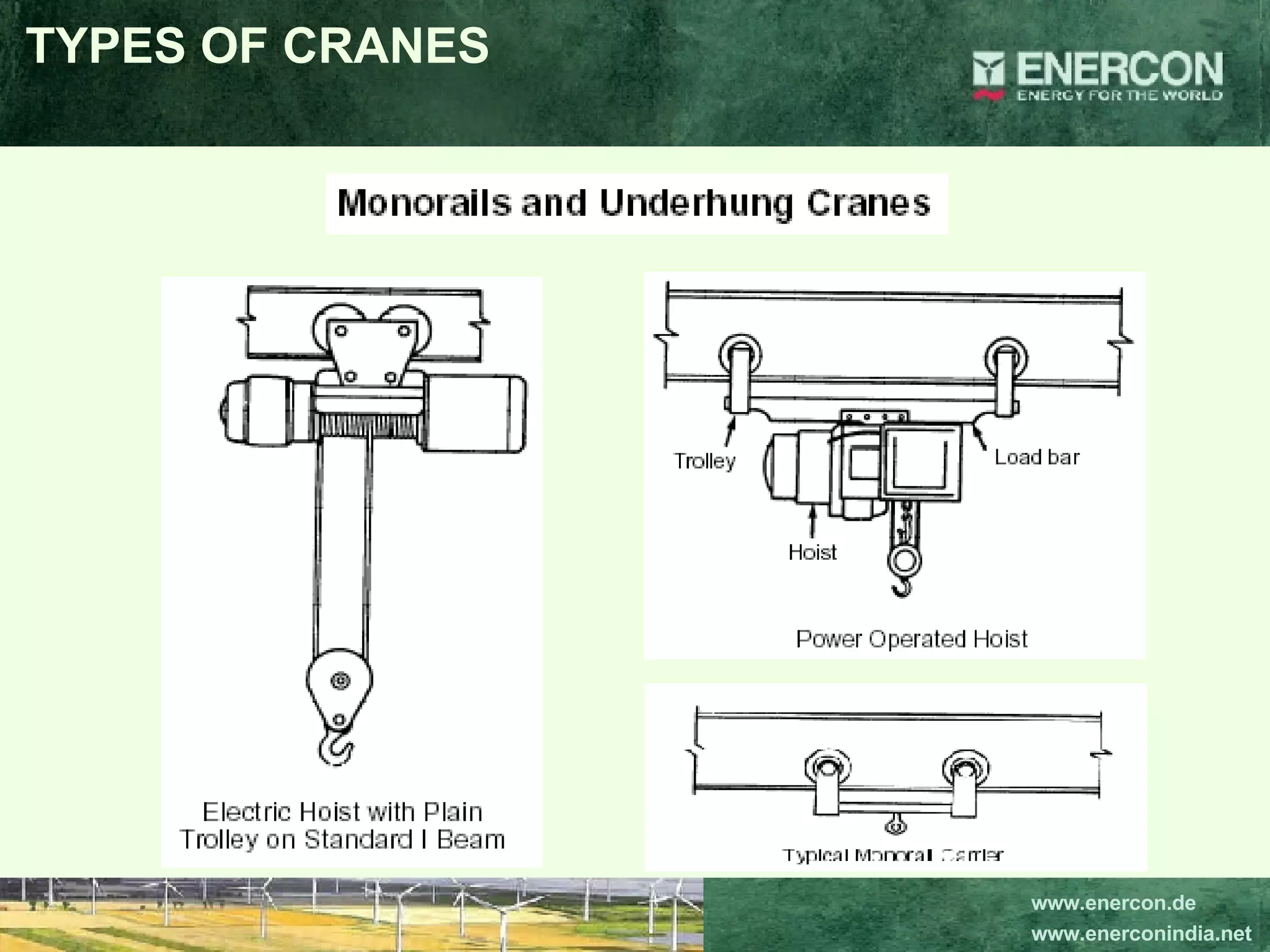

Cranes are used to lift and lower materials in construction and manufacturing. They can be mounted on vehicles or structures. Operators control the crane and communicate with workers through signals. The largest revolving cranes are found on ships. Common types include mobile, overhead, gantry and tower cranes. Unstable loads, lack of communication, lack of training, and inadequate maintenance or inspection are major causes of crane accidents that can injure operators or others in the area. Regular inspections by a competent person help ensure cranes are safe to use.