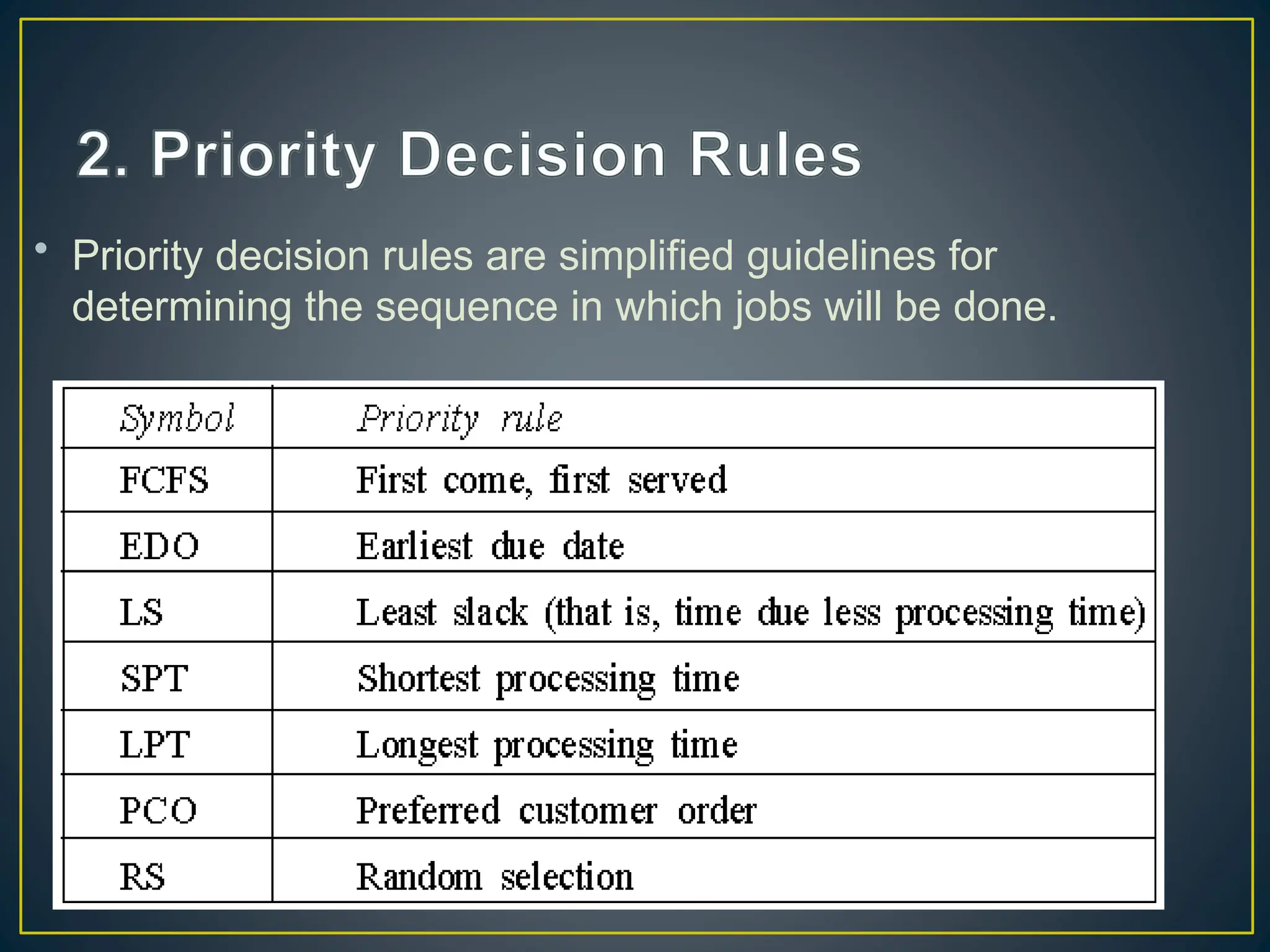

Scheduling involves planning the timing of operations in production to ensure completion by due dates, focusing on principles like optimum task size and production plan. Two primary methods are forward scheduling, which schedules jobs based on earliest availability, and backward scheduling, where jobs are timed to meet specific delivery dates. Various tools such as Gantt charts and mathematical programming methods are used to optimize the scheduling process across different types of industries.