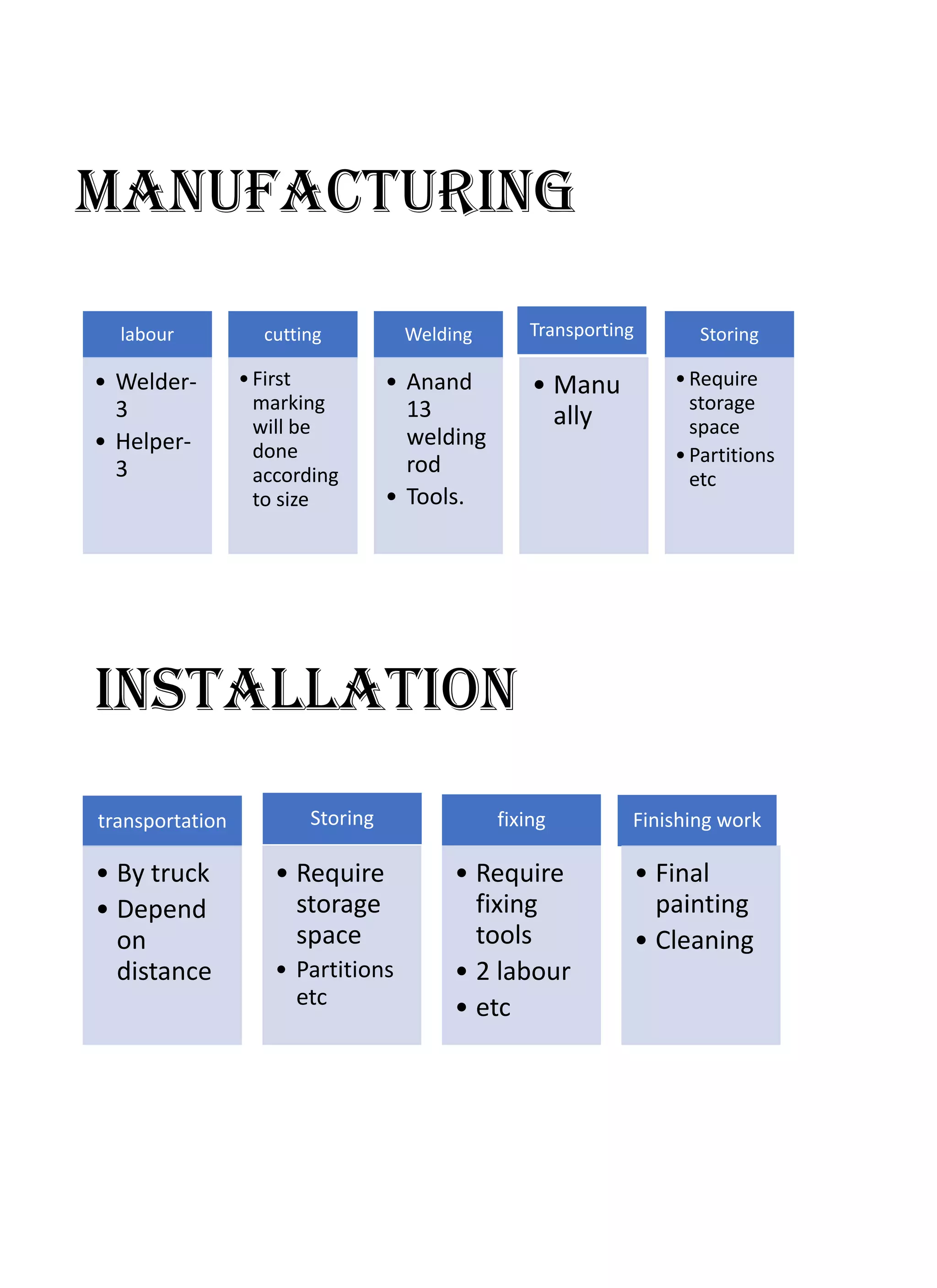

This project management report summarizes the window work project for Poornima University. The purpose of the project is to complete window installation in the Himalaya boys hostel and academic building by April 2020. There are approximately 80 windows to install. The project manager is Chandar Prakash Suthar. The report outlines the project timeline, tasks, costs, and manufacturing process for installing the windows. It also provides a work breakdown structure and Gantt chart to track the project schedule and progress.