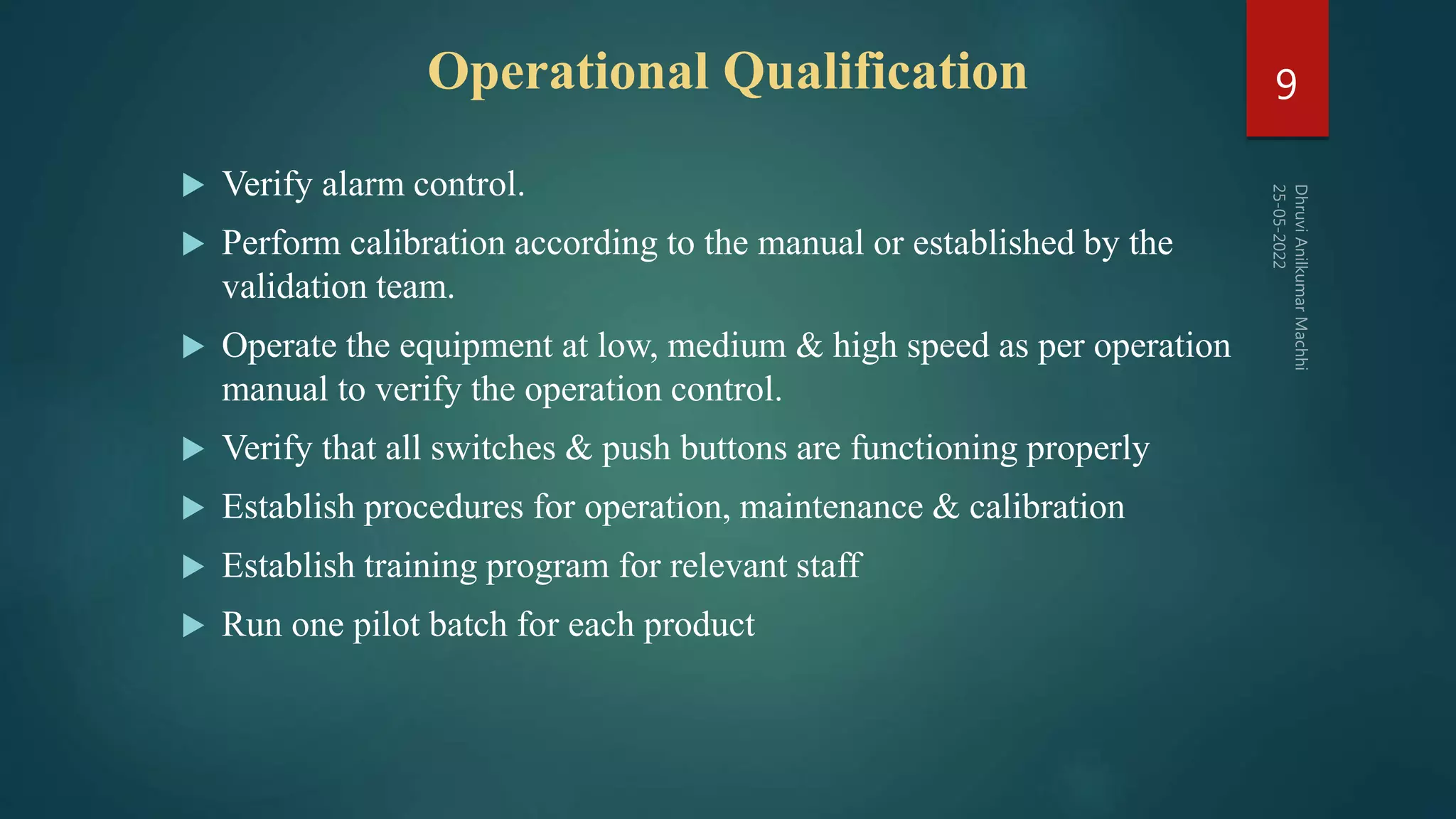

The document outlines the process and principles of tablet compression machines used in pharmaceuticals, detailing their construction, working mechanism, and various qualifications required for operation. It includes checklists for installation, operational, and performance qualifications, focusing on machine specifications, operational controls, and evaluation of tablet characteristics. References to additional resources are provided for further understanding of the qualification processes.