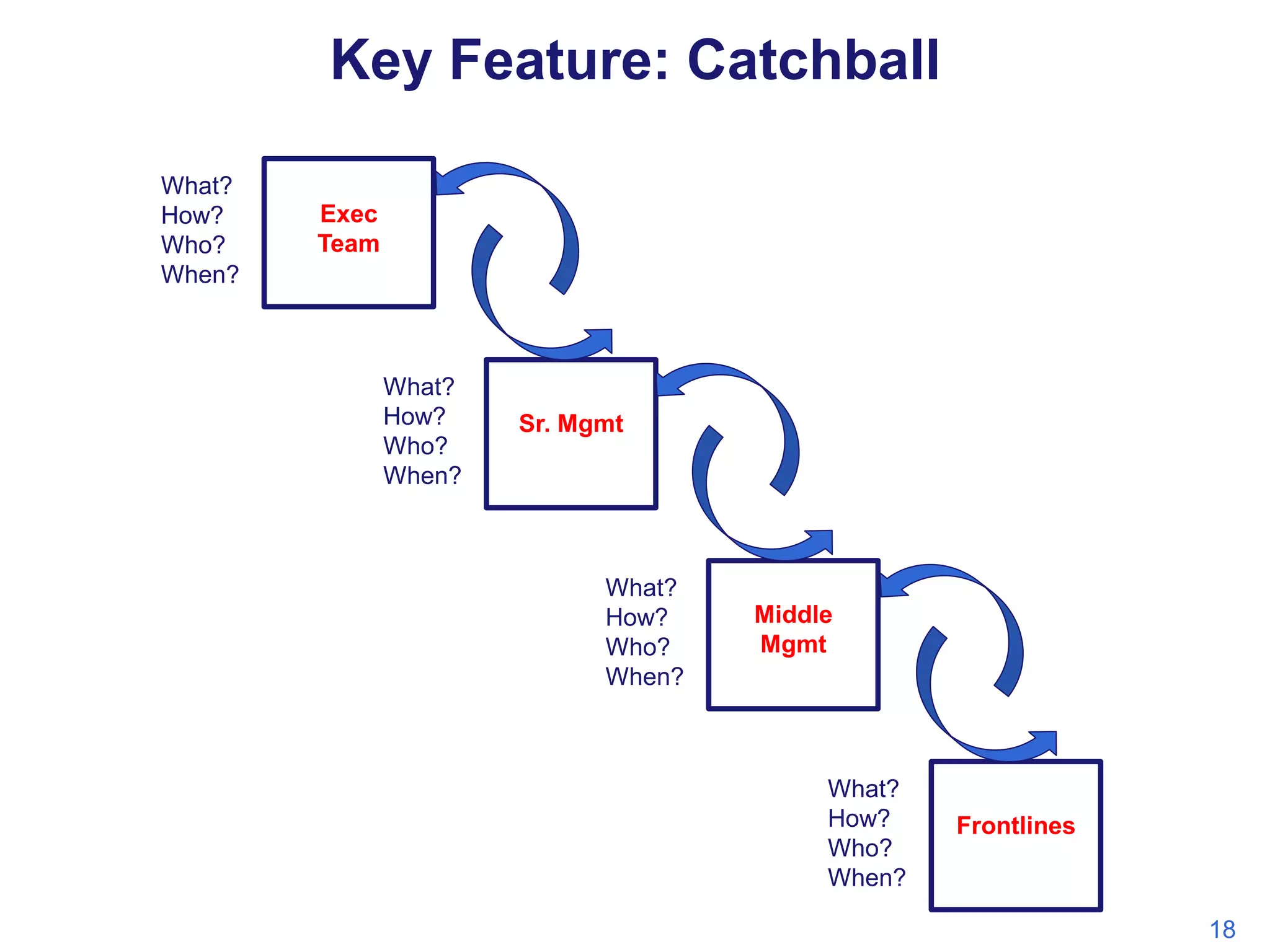

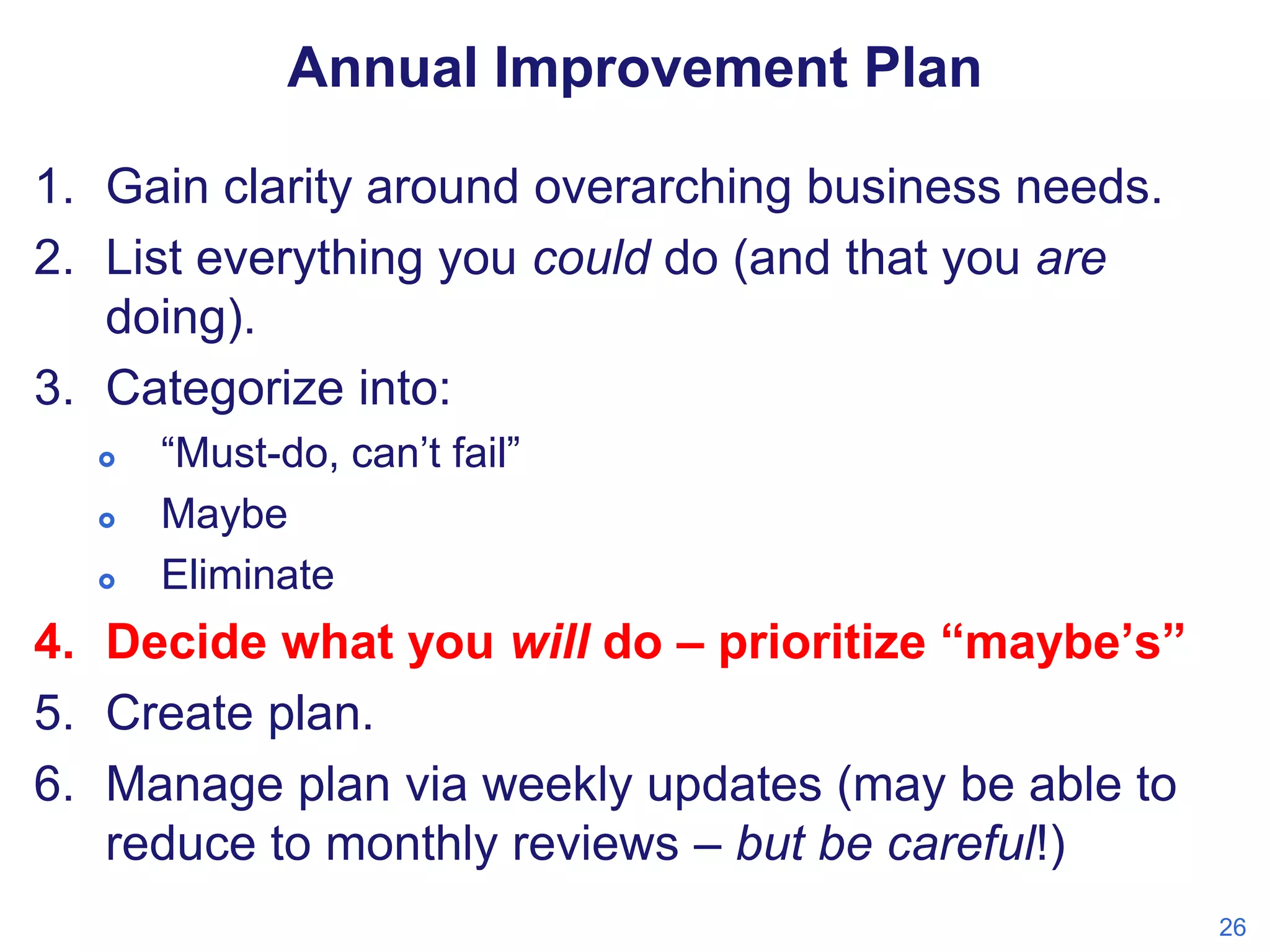

The document discusses strategy deployment, emphasizing the importance of focus and alignment in improving business performance. It outlines common challenges faced by organizations, such as conflicting priorities and the inefficiencies of multi-tasking, while presenting Hoshin Kanri as a solution for achieving organizational focus and accountability. Key requirements for successful strategy deployment include executive buy-in, clear goals, strong consensus-building, and a culture of accountability.