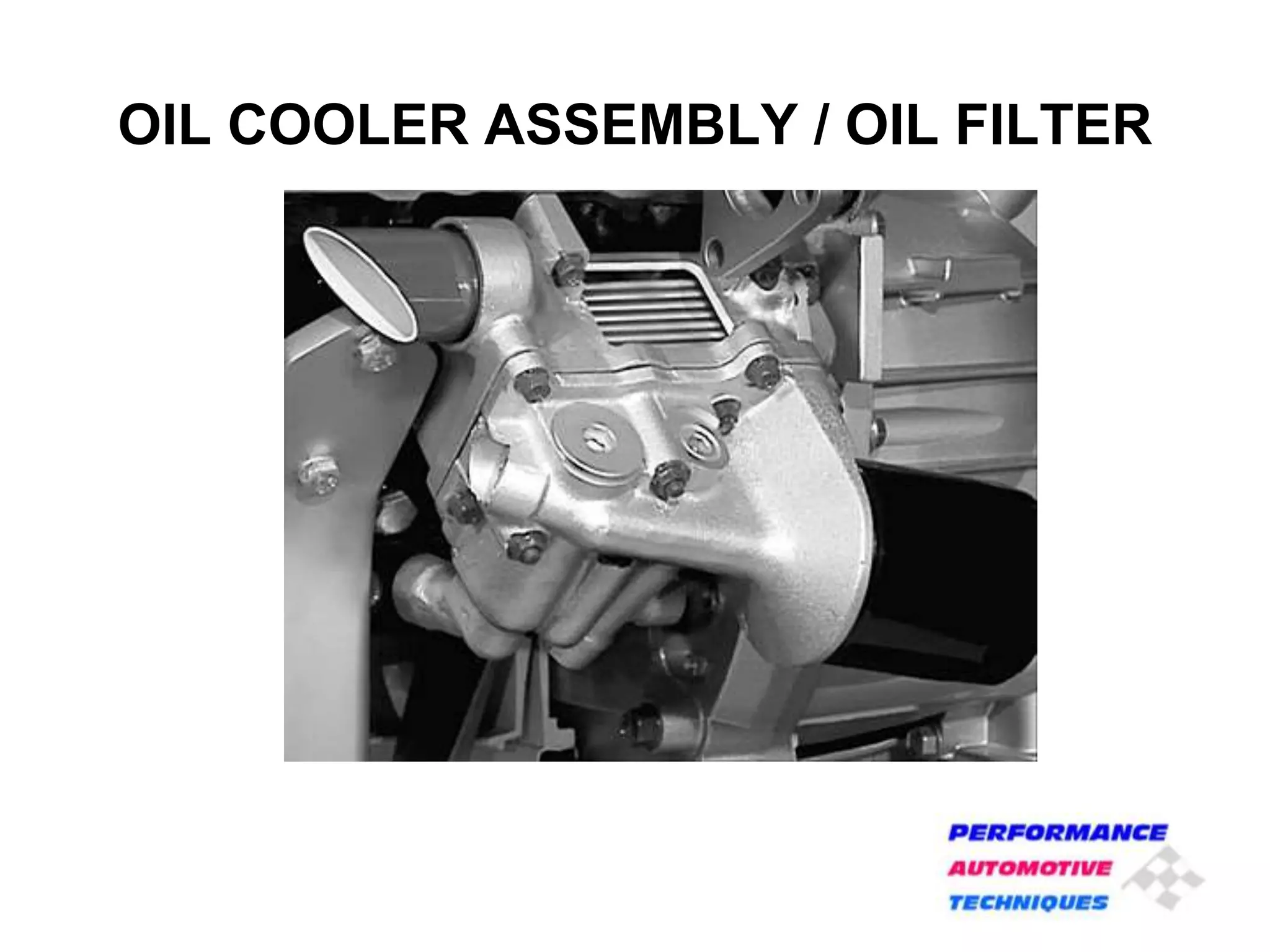

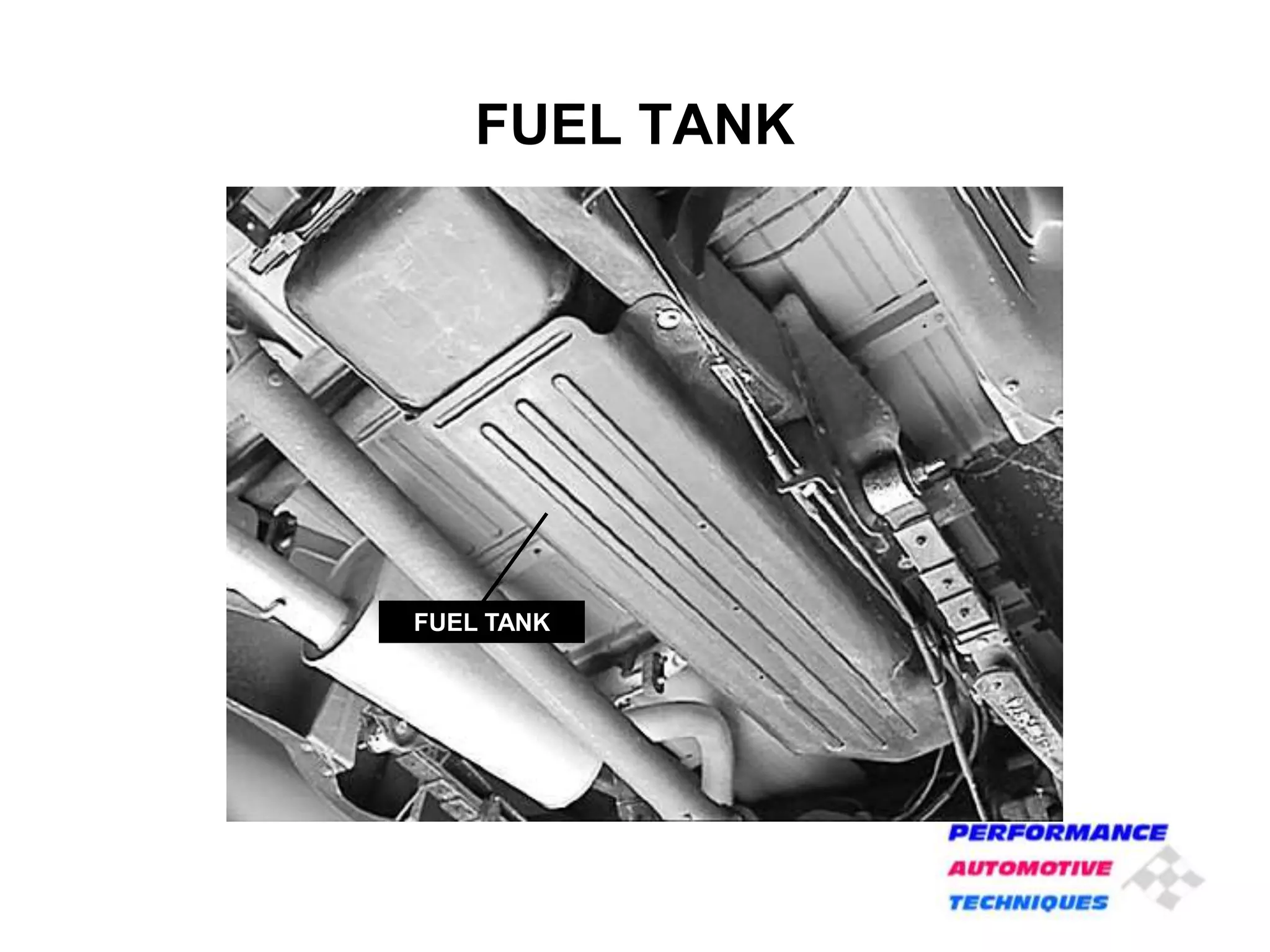

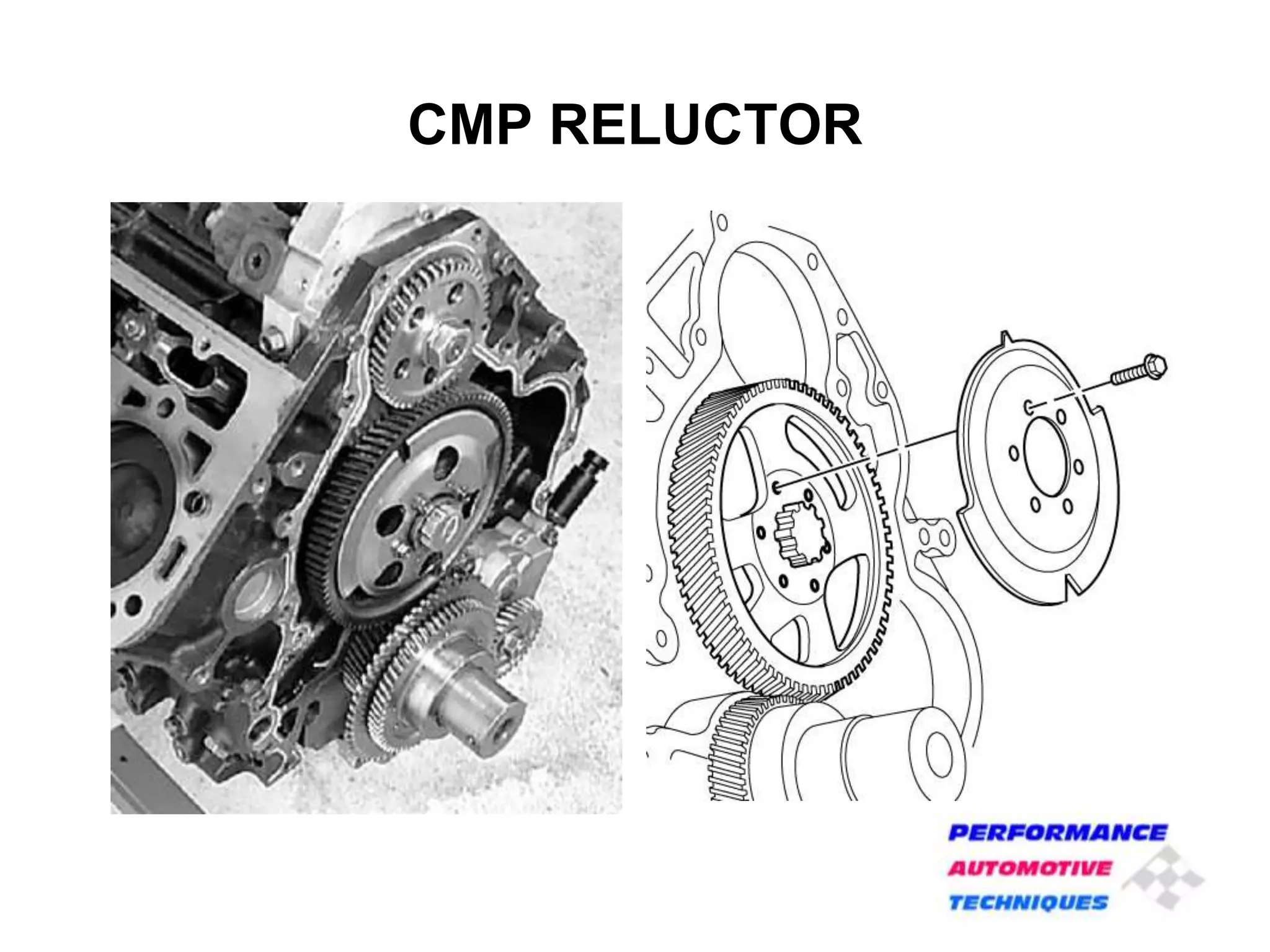

This document provides an overview and objectives of a training course on the GM Duramax 6.6L diesel engine. It introduces the instructor and covers topics that will be addressed, including the major components and systems of the engine like the lubrication, cooling, fuel, air intake and exhaust systems. Diagrams and specifications of the engine are presented. Diagnostics procedures using a scan tool are also discussed.